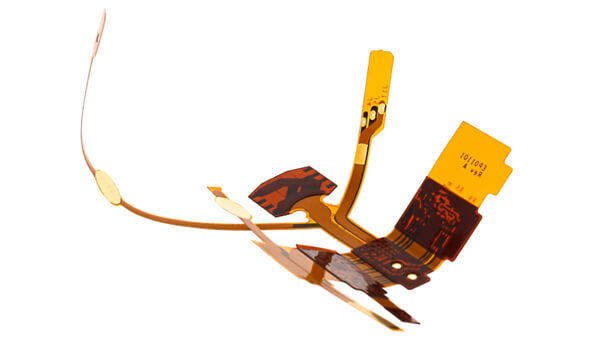

Flexible and rigid circuit technology provides significant additional capabilities beyond other available interconnection methods. These include reduced packaging requirements, increased reliability, better shock and vibration performance, better high-speed signal performance, better performance in harsh environments, and reduced cost opportunities. These items, single or combined, provide viable solutions that solve many of the design challenges encountered in the electronics industry.

Flexible and rigid designs are applied in all market segments and have been tested in the most demanding applications, including medical, aerospace, military, and high-reliability devices.

For most applications, flex and rigid-flex technology allows you to design circuits to fit the device instead of designing a device to fit the circuits. In many projects, this also allows you to add additional features or capabilities that otherwise would not have been possible due to space constraints.

Below you will find a list of the main advantages and capabilities of using flexible and rigid-flexible circuit technology.

Reduced packaging requirements

Improved reliability

Low weight

High-speed signal performance

Performance in harsh environments

EMI and RF applications

Cost saving opportunities

Component and connector compatibility

TCL Electronica’s team of engineers offers flexible and rigid circuit design services. During our application review and quotation process, we carefully review specifications, materials, and construction to minimize and eliminate any technical issues.

We also look for areas of opportunity to improve the design of the reliability and functionality of the flexible or rigid flexible circuit and ensure that there are no violations of IPC design standards. Cost reductions are also identified to generate an accurate quote based on a workable, reliable, and cost-effective design.

Corners within flexible bending areas

Staggered track positioning from layer to layer

Staggering the track placement layer by layer of your designs eliminates the "I-Beam" effect that improves the flexibility and reliability of your flexible circuit.

Fillets & Drops

Correct threads and tears eliminate stress concentrations and improve the reliability of the flexible PCB.

Vias within bending areas

This is not recommended. The presence of pathways within a bending area can cause a significant stress concentrator that can lead to breakage.

Stiffer terminations and Coverley

Proper reinforcement and roofing terminations prevent the creation of a significant stress concentrator within the flexible circuit.

As technology advances, devices become smaller and smaller and the requirements for data rates on printed circuit boards increase. Each flexible PCB is designed to perform a function within an assigned space, but it must also be manufacturable, must adhere to strict mechanical tolerances, and must be convenient.

With component scaling shrinking every year, it allows very small flexible PCBs to include significant functionality in addition to being a passive component to provide connectivity in certain applications.

How small can a flexible PCB be?

The size of the microcircuit depends on the application, but some of the key elements that are important to many customers are:

Applications for Flex Microcircuits

The continuous miniaturization of devices has led to printed circuit boards becoming smaller and denser and requiring greater capabilities. Applications we provide flexible mini-PCBs include:

TCL Elektronika is a leading miniature printed circuit board developer and manufacturer with an eye to industry tolerances and customer service. We offer comprehensive design and manufacturing services that can quickly adapt to meet any high or low volume demand.

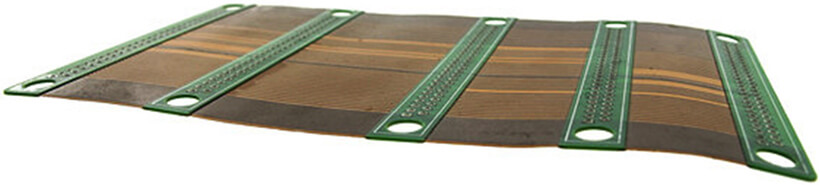

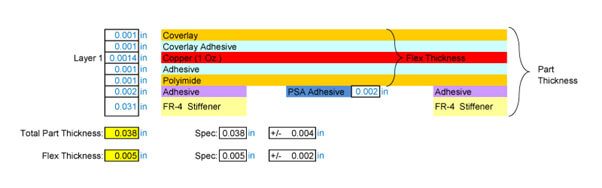

1-layer Flex PCB with optional FR-4 stiffeners and PSA

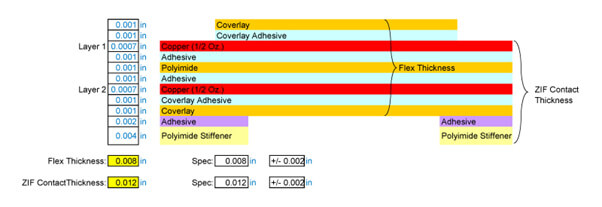

Flexible 2-layer circuit with ZIF contact fingers

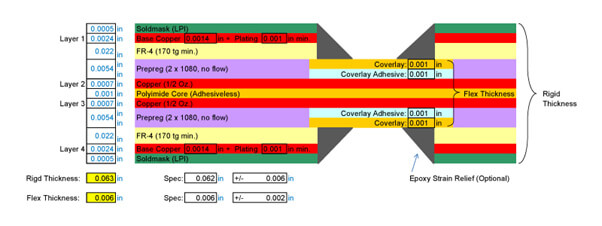

4-Layer Flexible Rigid PCB (2 Flexible Layers)

Every day, the medical industry saves lives thanks to the dedication of its working professionals and the medical devices available. Companies that design and manufacture medical devices, military, and aerospace applications.

As devices become more powerful as they arrive in smaller, portable sizes, customers are looking for circuits that offer higher capacities in compliance with medical regulations and standards. TCL Elektronika's rigid and flexible printed circuit boards provide the answers in terms of reliability, reliability, and safety.

Flexible circuits become the ideal choice

Medical applications are constantly looking for more functionality. In these cases, a multilayer board can handle all the control functions that would be needed. However, these applications also require greater flexibility and portability. Devices are getting smaller as they increase in complexity. From blood glucose monitors to heart monitors and infusion pumps for intravenous therapy, different packaging specifications can limit the amount of space inside the device for the circuits needed. In addition, many of the medical applications need to be portable to move from patient rooms and surgical sites without having to deal with all the cables and connections that can hinder movement.

Flexible circuit design and manufacturing investments

Our company's design and manufacturing capabilities are designed to meet the rigorous medical standards established for medical devices and components. Some medical devices that will be used directly on or within patients will need to be created using only acceptable materials that do not affect the quality of care or the patient's health. In addition, we also consider the composition of the materials used that will have to withstand extreme stresses, hot and cold temperatures and sterile environments.

Our engineers and manufacturing staff use the latest state-of-the-art features to meet the needs of medical devices. We provide higher impedance controls in our designs, application-appropriate trace widths, and higher current transport aspects to ensure that flexible and rigid PCBs meet performance requirements. We also create designs that will meet the high frequencies required by medical application when manufacturing flexible and rigid flexible PCBs that will fit the smallest and lightest devices.

Our manufacturing capabilities are designed to meet the standards of medical applications for clean and safe production environments. From providing a cleanroom to creating the printed circuit boards to using laser drilling and routing, plasma engraving and direct laser imaging to create via and control drilling depth curtains, our equipment is designed to offer greater lamination adhesion to prevent detachment and separation for the edge that will be bent and twisted in the application.

Medical Applications Using Flexible PCBs

The types of medical applications that can benefit from the use of flexible PCBs will be based on industry standards and regulations. Some applications may include:

When manufacturing portable devices, the spotlight of the design always shines on the printed circuit boards that will control the electronics and battery inside. Flexible and rigid PCBs solve many of the design problems that arise when it comes to creating thin, small, and light portable devices.

The technological needs of portable devices are being felt in multiple industries. When we often talk about portable devices, we automatically think of the electronics we use in our daily lives, such as smartphones, tablets, laptops and smartwatches. However, industries such as medical, military, catering, warehousing, construction, retail, and others also rely on portable devices so that workers can complete a range of tasks. From medical devices used during surgeries to military radar devices, these electronic devices require high speeds, consistent reliability, and complex controls. Turning to highly experienced engineers and production workers who have been working with flex and rigid-flex PCBs for more than 25 years allows customers to obtain the PCB for the specific portable device.

Medical Applications Using Flexible PCBs

Flexible and rigid PCBs offer versatile solutions for customers who want to design electronic components with space and weight limitations. All working components must fit and function properly without causing friction or the wires and connections getting tangled. Flexible circuits overcome this problem by having fewer connections and parts. Copper traces are engraved in the flexible polyamide substrate or in flexible rigid PTFE or FR-4 materials. This technique allows the printed circuit board to flex and bend around the working components. No additional space should be inserted into the device design while the customer receives a highly functional device that fits the application.

In addition, polyamide materials can be extremely small and lightweight, so they do not add any unwanted weight that can make the device too heavy to lift, carry or use. Customers can also put more features into the mobile device based on the required specifications.

Design and manufacture of Flex and Rigid-Flex PCBs

Portable devices face unique design and manufacturing challenges. Customers may require a circuit that offers flexibility and at the same time need something that can withstand shocks and fluctuations in ambient temperatures. Although flexible PCBs can provide the flexible look of the design, they may not be suitable for the shocks and temperature changes that will occur.

TCL Elektronika understands the challenges that arise during the design and production phases. We have developed a huge catalog and library consisting of the work we have done for various flexible and rigid-flex PCB products, as we use this information and our experience to guide customers overcome these obstacles so that they can get the portable device that is needed. In many cases, we will suggest a rigid and flexible PCB board for portable devices that will experience shocks and sudden changes in temperature.

With a rigid-flex board, the circuit still has the flexibility to adapt to the device. At the same time, rigid PCB sections provide greater stability to the overall central substrate to handle shocks and prevent breakage. In addition, the materials used with the rigid panel, such as PTFE and FR-4, can handle temperature fluctuations that can occur in different environments.

Both flexible and rigid PCBs are not limited to a single layer. We can supply multilayer circuits for greater multifunctionality. Here at TCL Elektronika, we invest in the production tools and equipment that will meet the tolerance specifications.

Applicazioni per PCB Flex e Rigid-Flex

The range of applications for portable devices that can benefit from flexible and rigid-flex PCBs is numerous. In addition to the commercial electronics of smartphones, cameras and tablets, these printed circuit boards are found in all medical, aerospace and military industries. Some applications include:

Special Certification Considerations

Portable devices may require certifications that will adhere to all local, state, and federal regulations, as well as national and industry standards. In Europe, China and the United States, many electronic devices must comply with RoHs (Restriction of Hazardous Substances in Electrical and Electronic Equipment) regulations, with the exception of medical devices and monitoring equipment. Companies in the medical and military sectors will also require manufacturers to adhere to industry regulations to ensure that appropriate materials and manufacturing processes are followed to comply with quality controls. Ourdesign and manufacturing facilities and staff are J-STD-001, ISO 9001 and IPCV Class III certified to provide superior capabilities for each customer's portable device design.

Date : 22-11-2021